Valves are critical components in the pharmaceutical industry, playing a crucial role in ensuring the safe, efficient, and sterile production of medications. These mechanical devices control the flow and pressure of liquids, gases, and slurries within a system, making them indispensable in the various stages of manufacturing. This article delves into the importance of valves in the industry, their types, applications, and the standards they must meet to ensure quality and safety.

Importance of Valves in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, precision and hygiene are paramount. Valves help achieve these by regulating the flow of ingredients, maintaining sterile conditions, and preventing contamination. They are used in processes such as mixing, batching, transferring, and filling, where precise control over the flow and pressure of fluids is essential. The reliability and performance of valves directly impact the quality of the final product and the efficiency of the manufacturing process.

The Valve Check Advantage:

At Valve Check, we pride ourselves on delivering cutting-edge valve solutions tailored to meet the evolving needs of the pharmaceutical industry. With decades of experience and a commitment to innovation, we have established ourselves as industry leaders, trusted by businesses worldwide for our quality and reliability.

Our product lineup boasts a comprehensive range of valves, meticulously engineered to deliver unparalleled performance and durability. From Check Valves to Relief Valves, we offer a diverse portfolio to cater to a wide spectrum of applications.

What sets Valve Check apart is our relentless pursuit of excellence. We leverage the latest advancements in technology and manufacturing techniques to ensure that our valves meet the highest standards of quality and precision. Each valve undergoes rigorous testing and inspection to guarantee flawless operation under demanding conditions, providing our customers with peace of mind and confidence in their systems’ performance.

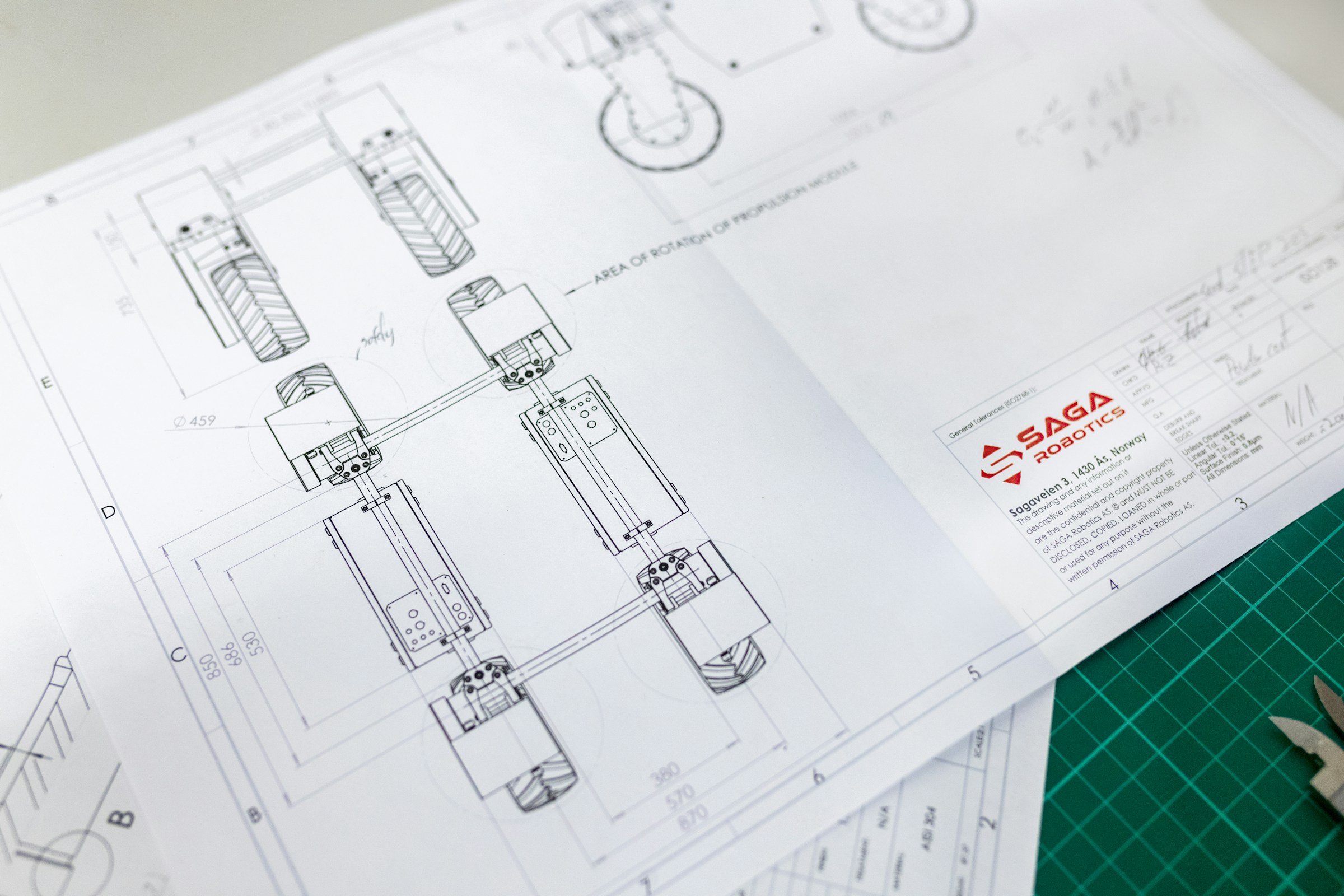

Custom Solutions in Pharmaceuticals

Furthermore, we understand that every customer has unique requirements. That’s why we offer customizable solutions, working closely with our clients to design valves that perfectly align with their specific needs and applications. Whether it’s customizing materials, sizes, or performance parameters, our dedicated team of engineers is committed to delivering tailored solutions that exceed expectations.

We provide pharmaceutical solutions.

Shop for our quality pharmaceutical valves.

Valves are indispensable in the pharmaceutical industry, where precision, reliability, and hygiene are critical. They are used in various applications, from sterile processing to utility systems, ensuring safe and efficient production By meeting stringent standards and regulations, valves help maintain the quality and safety of pharmaceutical products, ultimately contributing to the health and well-being of patients worldwide.

Photos by: Roberto Sorin, Crystal Kwok, ThisisEngineering RAEng, and Glsun Mall on Unsplash